What is LRV?

Light Reflectance Value is the total quantity of visible light reflected by a surface at all wavelengths and directions when illuminated by a light source. It is used in architecture and interior design to determine how much light a surface reflects or absorbs. Essentially, it is a universal value used to assist with determining visual contrast. LRV represents a relative darkness to lightness value rather than being in reference to any particular colour.Why is LRV important?

The Equality Act 2010 states that all new or refurbished public buildings should offer equal ease of access and use to all, regardless of disability, age or gender, ensuring safe entry, exit and passage through the building. In relation to supporting visual impairments, British Standard BS8000-2:2018 states there must be adequate visual contrast between building surfaces and their surrounding areas – this includes fixtures and fittings such as assistive products. People with good vision can easily recognise the hue (nature of the colour) and chroma (intensity) of the objects and structures around them – but good contrast still makes good sense when designing spaces. Identifying the nature and intensity of colour is more difficult for people with sight loss – although it’s worth noting that most people who are registered blind still have some degree of vision in colour, and only 5% can see nothing at all. Even people in this group will have some sensitivity to light vs shade, making contrast an important tool for improving accessibility.The LRV scale

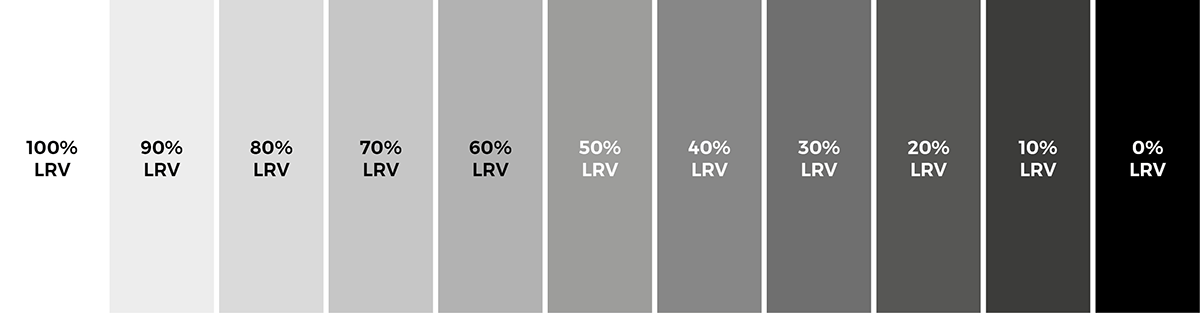

Referencing the chart above, the LRV scale runs from 0, a perfect light absorbing surface finish which can be assumed to be totally black, up to 100% which is a perfect reflective surface finish of brilliant white. It’s rare to find these ‘perfect’ examples in everyday environments. For example, a wall painted in Brilliant White Matt emulsion will usually only return a value of about 85. A completely black surface will usually have a value greater than 0. The importance of LRV lies not so much in the value given to each surface, but in the contrast between items. Light reflectance values for an object’s finish may be quoted as very specific numbers, but it’s the number of points of difference between the values that really matters. For instance, the guidance from Approved Document M states that:- The LRV between two surfaces should be greater than 30 points

- Where illumination on a surface is greater than 200 lux, the difference in LRV should be a minimum of 20 points

LRV in a DOC M washroom

There are a number of key elements and surfaces to consider when it comes to LRV compliance in a washroom. These include built aspects of the space as well as any Doc M accessories we might add. For instance, it’s vital to have contrast between the walls and the floor, and between the doors or door frames and the walls, so that people can see where they’re going. The contrast between NYMAS Group products and the surface they are mounted on is vital for an Approved Doc M space. Examples include contrast between:- Grab Rails/Hinged Rails/Back Rests and Shower Seats and the wall they are mounted on

- Sanitary fittings and walls

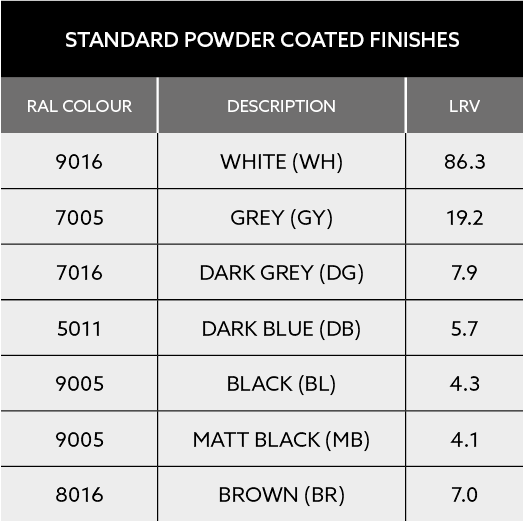

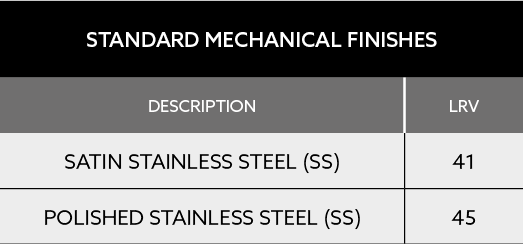

NYMAS Group standard finishes and their LRV figures

We offer support to architects, specifiers and contractors when it comes to making appropriate surface finish selections for LRV compliance. For the most part, it is the metallic parts of our products that have the greatest effect on visual contrast in a Doc M compliant space. Our standard range of finishes has been carefully curated to provide a range of options when planning a compliant washroom.

PVD finishes are available in both Polished (P) and Satin (S) finish, please add P or S to the end of the reference code when requesting finishes (e.g P01P = Polished Nickel; P01S = Satin Nickel).

Please note: The LRV values quoted above are for the flat colour. Satin or polished finishes can skew the given figure and make the LRV difficult to measure accurately. LRV Values are accurate to +/- 2.0 LRV points.

Finally, when it comes to accessible design, our experienced team is on hand to answer your questions. Call us on +44 (0)1642 710 719, or email sales@nymas.co.uk for expert advice and product samples.

PVD finishes are available in both Polished (P) and Satin (S) finish, please add P or S to the end of the reference code when requesting finishes (e.g P01P = Polished Nickel; P01S = Satin Nickel).

Please note: The LRV values quoted above are for the flat colour. Satin or polished finishes can skew the given figure and make the LRV difficult to measure accurately. LRV Values are accurate to +/- 2.0 LRV points.

Finally, when it comes to accessible design, our experienced team is on hand to answer your questions. Call us on +44 (0)1642 710 719, or email sales@nymas.co.uk for expert advice and product samples.